Description

These fine switches are great for detecting subtle events, such as when a robot arm has reached the top or bottom of its motion.

- Bendable sheet metal switch “arm” is very versatile

- Useful as a trigger in a variety of applications

- Functionality is pre-programmed in the VEX ARM® Cortex®-based Microcontroller

Overview

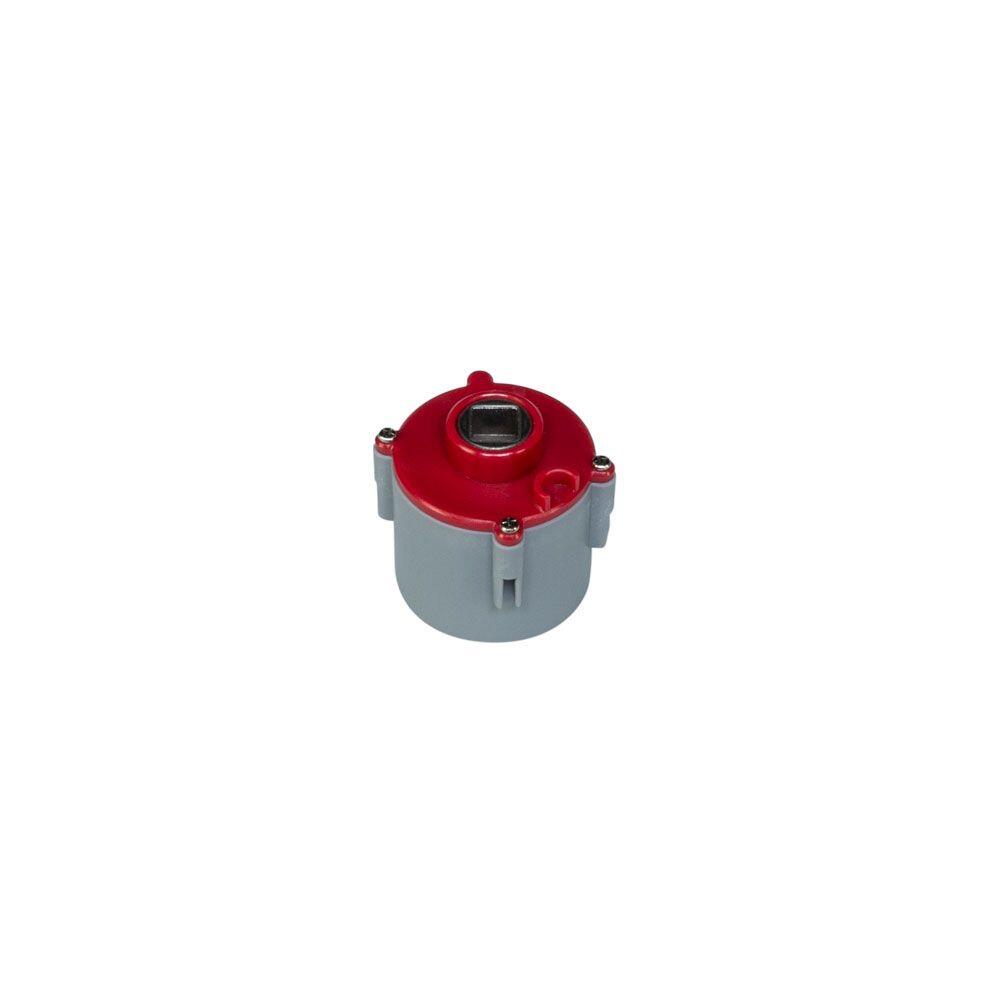

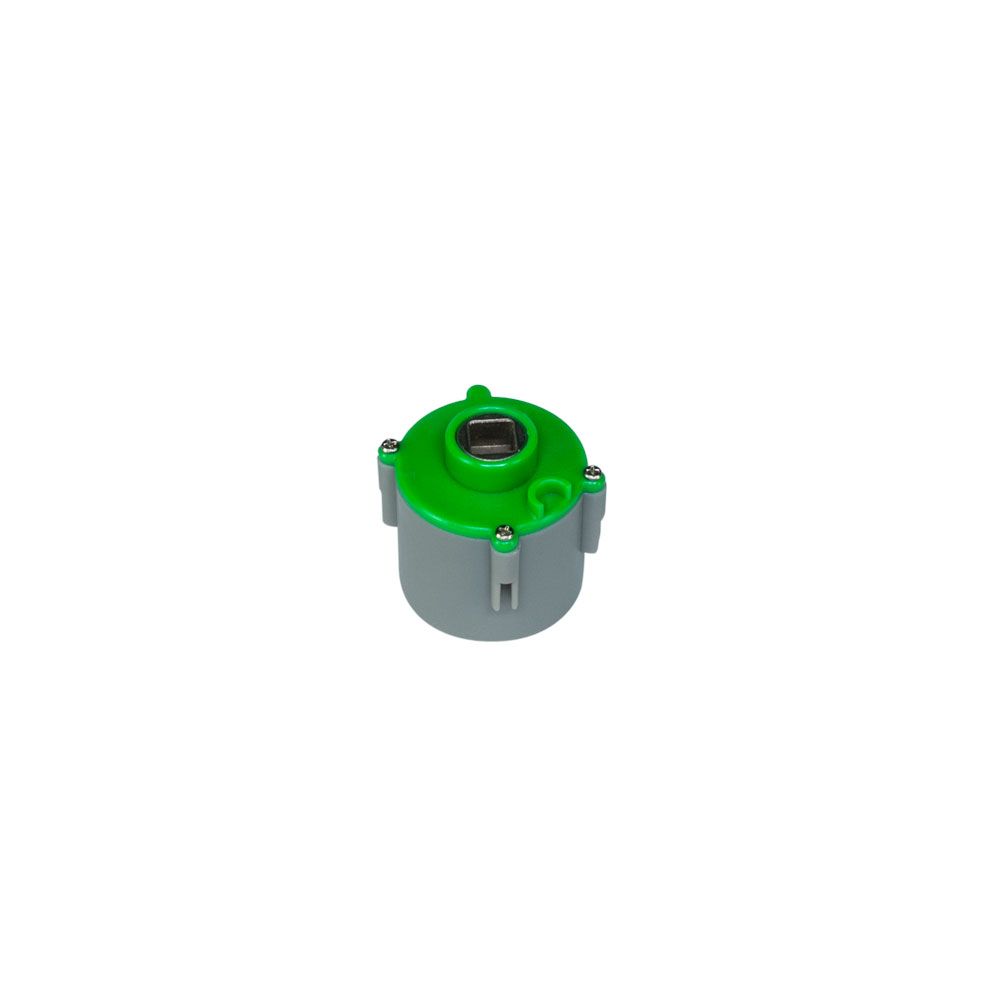

Limit Switch Sensor Signal: The limit switch sensor is a physical switch. It can tell the robot whether the sensor’s metal arm is being pushed down or not.

Switch Type: SPDT microswitch, configured for SPST Normally Open behavior. Behavior: When the limit switch is not being pushed in, the sensor maintains a digital HIGH signal on its sensor port. This High signal is coming from the Microcontroller. When an external force (like a collision or being pressed up against a wall) pushes the switch in, it changes its signal to a digital LOW until the limit switch is released. An unpressed switch is indistinguishable from an open port.

Benefits: Limit switches expand the functionality of robots by allowing controlled motion in moving components (e.g., gripper arm). They also allow the robot to better detect its surroundings, by detecting collisions with external objects.

Functions

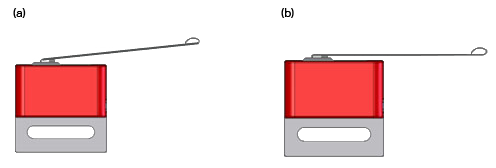

The limit switch is used to determine the proximity of equipment (the Applications section illustrates a few examples). The limit switch can output only two signals: ON and OFF. It outputs a digital ON signal when the lever arm is depressed and a digital signal OFF when the lever arm is not depressed (see Figure 2 below). External forces, such as collisions, produce a digital ON signal, which remains ON until the lever arm is released.

Applications

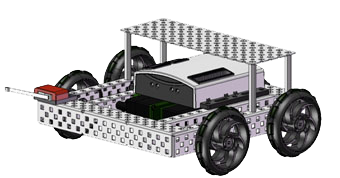

Limit switches provide the capability to limit action in programmed behaviors. For example, a robot can be programmed to stop forward motion if the switch is triggered ON. Figure 3 below shows a limit switch placed on the front of Squarebot. If this Squarebot were to run into a wall or another obstacle, the limit switch would be triggered ON and the robot would stop, as programmed.

Figure 3. Squarebot with limit switch

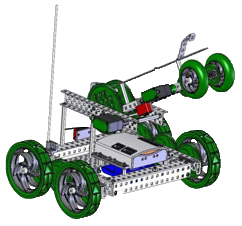

Similarly, triggering the limit switch can tell the microcontroller to stop rotating robot components, such as arms. A Programming Kit is needed to implement this (see Programming Resources for sample codes).

Figure 4. Protobot utilizing a limit switch to stop a rotating arm

Figure 5 shows a close-up of the limit switch placement on Protobot. As the limit switch runs into the horizontal bar below the lever arm, the limit switch is triggered ON and the microcontroller stops the arm from rotating.

Figure 5. Protobot limit switch close-up

Range Limits

The limit switch will be either in the ON or OFF state. The torque required to change from OFF to ON (i.e., depress the lever arm) for an unmodified limit switch is approximately 0.005N-m, which is equivalent to applying approximately 0.03lb 2in away from the lever arm pivot point. Figure 6 below shows the location of the pivot point. If the limit switch is modified this torque will vary. If necessary the specific torque or amount of force required to trigger the limit switch at a specific distance can be calculated using basic torque equations.

Figure 6. Side view of limit switch showing lever arm pivot point

| Product Specs | Limit Switch Specifications |

|---|---|

| Inputs |

|

| Outputs |

3-Wire Cable Connects to a digital input.

|

- (2) Limit Switch Sensors

- Compatible with all VEX Microcontrollers and 3-Wire Extension Cables

There are no reviews yet.